As someone who has worked in PVC fabric production and coating technology for over a decade, I’ve seen the same question come up again and again from buyers: “Which finish should I choose—gloss or matte?” The answer is rarely just a matter of aesthetics. The finish affects durability, performance, cost, and even compliance with end-use requirements.

In this article, I’ll break down the differences between gloss PVC fabric and matte PVC fabric, based on real-world use cases, industry standards, and practical purchasing experience. If you’re a buyer, product developer, or designer, this guide will help you make a confident decision.

What is PVC Fabric Coating?

PVC fabric coating is the process of applying polyvinyl chloride (PVC) to a base textile substrate such as polyester, nylon, or fiberglass. This coating creates a composite material with enhanced properties, including waterproofing, chemical resistance, strength, and surface finish control.

A PVC-coated fabric typically consists of three layers:

• Base fabric (substrate): Provides tensile strength and dimensional stability.

• PVC coating layer: The functional layer that gives waterproofing and surface properties.

• Surface finish: The outermost layer that determines gloss level, texture, and appearance.

The key to understanding PVC fabric coatings is that the finish is not just cosmetic. It’s part of the material’s performance system. A gloss finish might reflect more light and look “clean,” but a matte finish can offer better hide for scratches and stains, and sometimes improved UV stability depending on the formulation.

Gloss Finish vs. Matte Finish: Key Differences

A. Visual and tactile differences

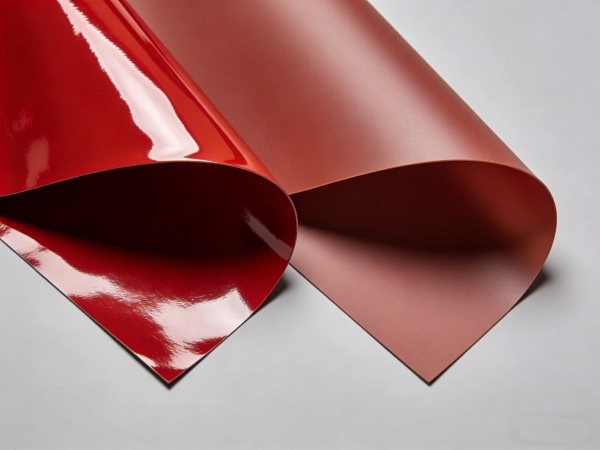

A gloss PVC fabric has a shiny, reflective surface. It looks smooth and high-end, especially under bright lighting. In contrast, matte PVC fabric has a low-sheen finish that appears more natural and less reflective.

Why this matters:

In many industries, appearance affects brand perception and product positioning. For example:

• Gloss PVC is often chosen for fashion-forward products or high-visibility signage.

• Matte PVC is preferred for industrial applications, architectural membranes, or products where glare is undesirable.

B. Surface texture and feel

Gloss coatings tend to feel smoother and sometimes slightly stiffer. Matte coatings can feel softer and more fabric-like because of their micro-texture.

C. Light reflection and color perception

Gloss surfaces reflect more light, making colors appear brighter and more saturated. Matte surfaces diffuse light, resulting in a softer color tone and less glare.

Practical tip:

If you’re using colored PVC fabric for branding or logos, gloss coating may deliver stronger color pop. Matte coating can deliver a more premium, understated look.

Durability Comparison: Gloss vs. Matte PVC

This is where buyers often get surprised: the finish can influence performance, not just looks.

A. Scratch resistance

A gloss surface tends to show scratches more easily because the reflective surface highlights surface defects. Matte surfaces diffuse light, which can make scratches less visible.

Real-world example:

In applications like outdoor awnings, truck covers, or industrial curtains, a matte finish often maintains a “cleaner” appearance longer because minor abrasions are less noticeable.

B. Abrasion and wear

Both gloss and matte PVC coatings can achieve high abrasion resistance, but the formulation and coating thickness matter more than the finish alone.

In my experience, a matte finish often feels more durable because it is frequently paired with higher filler content or textured surface additives that enhance wear resistance.

C. Stain resistance

Gloss PVC coatings are usually easier to wipe clean due to their smooth surface. Matte coatings may trap dirt in micro-texture, requiring more thorough cleaning.

Important note for buyers:

If you expect frequent cleaning or chemical exposure (e.g., food processing, medical environments, or heavy industrial use), ask your supplier about PVC surface additives such as anti-fouling agents or oil-resistant formulations.

D. UV stability and fading

UV resistance is heavily influenced by the PVC formula and UV stabilizers, not just the finish. However, gloss surfaces can show fading more dramatically because the shiny surface highlights changes in color and sheen.

In high UV environments, a matte finish may appear more stable over time, even if both coatings have similar UV stabilizers.

Best Applications for Gloss PVC Fabric vs. Matte PVC Fabric

Here’s a practical breakdown of where each finish excels:

Gloss PVC Fabric: Best Use Cases

• Retail displays and signage: High reflectivity attracts attention.

• Fashion accessories: Gloss gives a premium, modern look.

• Outdoor banners: Colors appear vivid and bold.

• Inflatables and decorative structures: Gloss highlights curves and shapes.

Matte PVC Fabric: Best Use Cases

• Industrial curtains and tarpaulins: Less glare, more practical.

• Tent and canopy materials: Better hide for dirt and scratches.

• Architectural membranes: Premium, non-reflective appearance.

• Automotive interiors: Reduces reflection and looks more professional.

Why this matters:

If you’re choosing PVC fabric for a product line, aligning the finish with the application can reduce maintenance costs and improve user satisfaction.

How to Choose the Right Finish for Your Project

Choosing between gloss and matte PVC fabric coatings requires a structured approach. Here are the key factors I recommend evaluating:

1. End-use environment

• Outdoor exposure: Consider UV stability and dirt resistance.

• Indoor use: Consider aesthetics and cleaning frequency.

2. Appearance requirements

• Brand positioning: Gloss for high-impact visuals, matte for premium subtlety.

• Lighting conditions: Matte is better in bright light to reduce glare.

3. Durability needs

• Abrasion resistance: Look for higher coating weight and stronger base fabric.

• Scratch visibility: Matte is usually more forgiving.

4. Cleaning and maintenance

• Gloss surfaces clean easier but show fingerprints.

• Matte surfaces hide marks but may need deeper cleaning.

5. Budget and cost

Gloss PVC coatings often require higher-quality surface finishing and polishing processes, which can raise cost. Matte coatings may be more cost-effective, but the final price depends heavily on formulation and additives.